Troubleshooting Your Vermont Evaporator Sugar Cube RO System: Conquering the Dreaded Air Leak

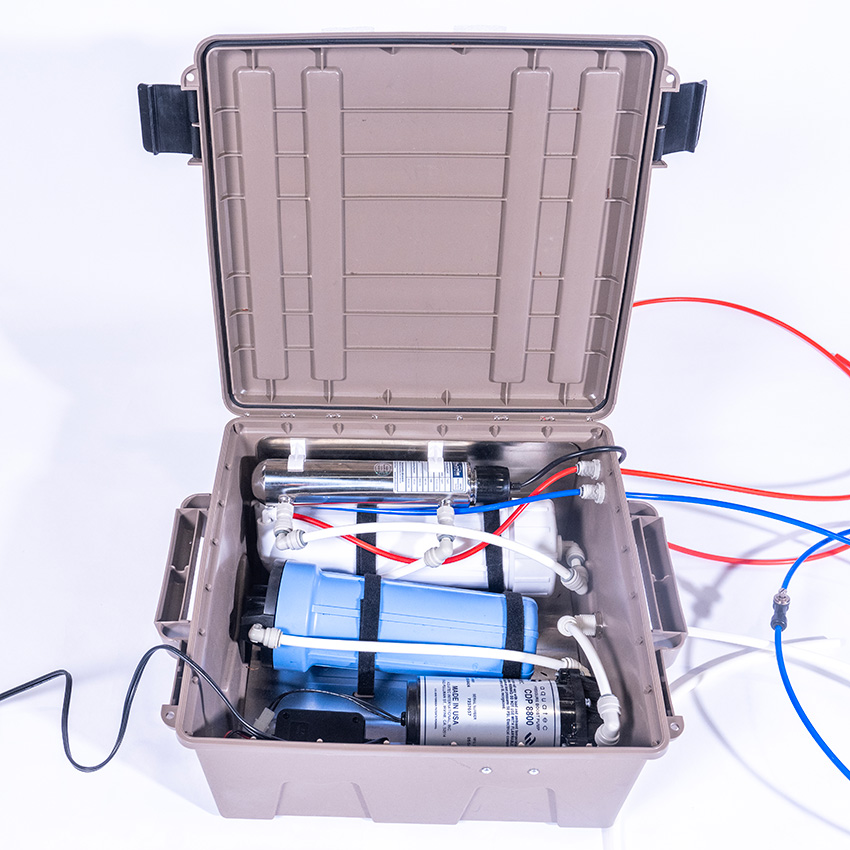

So, you’ve got a Vermont Evaporator Sugar Cube Reverse Osmosis System, and you are ready to make some delicious maple syrup. But something’s not quite right. Maybe the permeate flow is slow, or the system isn’t reaching the expected pressure. More often than not, the culprit is an air leak. These tiny infiltrators can wreak havoc on your RO system’s performance, so understanding how to identify and fix them is crucial. Here’s how to conquer the dreaded air leak!

This post focuses specifically on troubleshooting air leaks in your Sugar Cube system, and how to address them, especially when it comes to those sometimes tricky press-fit fittings.

The Importance of an Air-Tight System

Your RO system relies on pressure to force water through the membrane, separating the pure permeate from the concentrate. Any air leaks disrupt this delicate balance. Air in the system can lead to:

- Reduced permeate flow: Air takes up space that should be occupied by water, hindering the flow of purified water.

- Lower pressure: Leaks reduce the overall pressure within the system, impacting the efficiency of the RO process.

- Increased concentrate flow: More water (and therefore sugar) ends up in the concentrate stream, reducing the overall yield of your syrup operation.

- Potential damage to the system: In severe cases, air leaks can lead to premature wear and tear on components.

Hunting Down the Leaks: A Step-by-Step Approach

The Sugar Cube uses press-fit fittings, which are generally reliable but can sometimes be a source of leaks if not properly installed. Here’s a systematic approach to finding those pesky air leaks:

- Visual Inspection: Start with a thorough visual check of all tubing connections, fittings, and the RO housing itself. Look for any signs of loose connections, kinks in the tubing, or cracks in the housing.

- The “Soapy Bubble” Test: Mix a small amount of dish soap with water. Apply the soapy solution to all connections, fittings, and around the RO housing. If you see bubbles forming, you’ve found your leak! The escaping air is creating the bubbles.

- Focus on the Press-Fit Fittings: Pay special attention to the press-fit fittings. These require the tubing to be fully inserted to create a proper seal. Sometimes, it can feel like the tubing is in, but it might not be seated completely.

The Key to Press-Fit Fittings: Full Insertion!

This is so important, it deserves its own section. Press-fit fittings rely on a tight seal between the tubing and the fitting. If the tubing isn’t fully inserted, you’ll almost certainly have a leak.

- How to Ensure Full Insertion:

- Cut the tubing cleanly: Use a sharp tubing cutter to ensure a clean, straight cut. A jagged or angled cut can prevent proper sealing.

- Push firmly and evenly: When inserting the tubing, apply firm and even pressure. You should feel the tubing “click” or seat into place.

- Double-check: After insertion, give the tubing a gentle tug to ensure it’s securely locked in. If it comes out easily, it wasn’t fully inserted.

- Check the RO Housing: Inspect the RO housing for any cracks or damage. Tighten the housing cap if necessary, but be careful not to overtighten.

- Inspect the other components: Check the other components of the system, such as the pump and any other connections, for any signs of leaks.

Fixing the Leaks

- Loose Connections: Tighten any loose fittings.

- Improperly Inserted Tubing: Remove the tubing from the press-fit fitting and re-insert it, ensuring full insertion as described above. You may need to trim the end of the tubing if it appears damaged or uneven.

- Damaged Components: Replace any damaged components, such as cracked fittings or tubing.

Prevention is Key

- Use the right tools: Always use a proper tubing cutter for clean cuts.

- Follow the manufacturer’s instructions: Refer to the Vermont Evaporator Manual for specific instructions on assembling and maintaining your Sugar Cube system.

- Regular maintenance: Periodically inspect your system for any signs of wear or leaks.

By understanding the importance of an air-tight system and following these troubleshooting steps, you can keep your Vermont Evaporator Sugar Cube RO running smoothly and efficiently, producing the best possible maple syrup. Happy sugaring!